Curtain rails, also known as curtain tracks, are essential components in window treatment systems, providing the functional and aesthetic framework for hanging curtains and drapes. Their performance can significantly impact the ease of use, durability, and overall appearance of window coverings. Below, we explore key aspects of curtain rail performance, including material quality, design features, load-bearing capacity, and installation considerations.

1. Material Quality

The performance of a curtain rail heavily depends on the material from which it is made. Common materials include aluminum, steel, and plastic.

– Aluminum: Known for its lightweight and durability, aluminum curtain rails are resistant to rust and corrosion, making them ideal for various environments. They offer a sleek appearance and are suitable for both residential and commercial use.

– Steel: Steel rails are robust and capable of supporting heavier curtains. They are often used in spaces where durability and strength are crucial. However, they may require a protective coating to prevent rust.

– Plastic: Plastic curtain rails are lightweight and cost-effective. While they may not support heavy curtains as effectively as metal options, they are easy to install and maintain.

2. Design Features

Curtain rails come in various designs to accommodate different needs and preferences. Key design features that affect performance include:

– Track Type: Curtain rails can be either straight or curved, allowing for flexible installation in different window configurations. Curved tracks are particularly useful for bay windows or circular drapery installations.

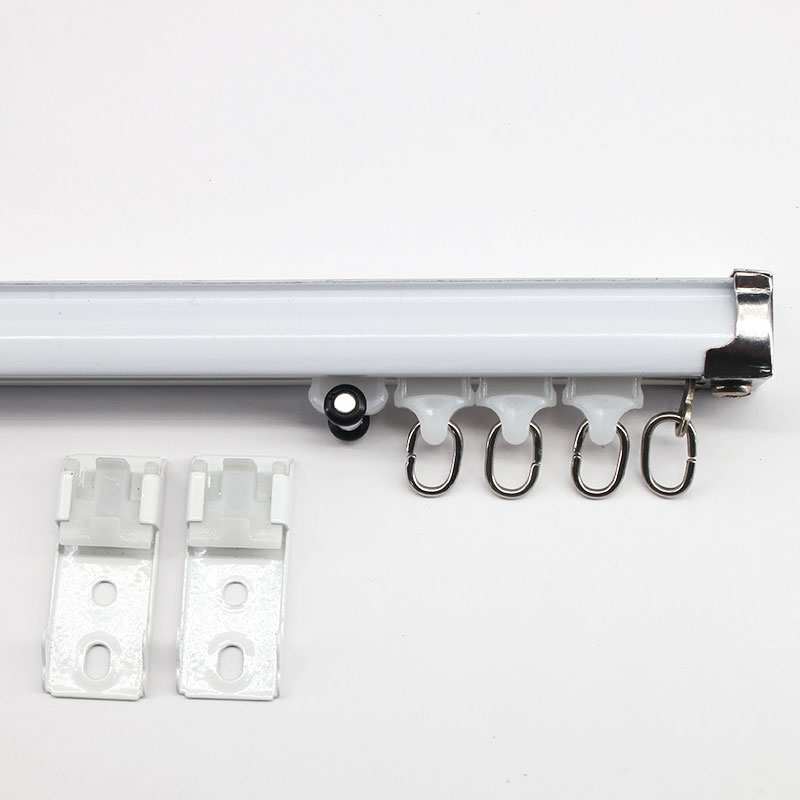

– Roller Mechanism: The smooth operation of curtains depends on the quality of the roller mechanism within the rail. High-performance rails feature smooth-running rollers or gliders that ensure easy movement of curtains.

– Compatibility: Some curtain rails are designed to be compatible with various types of curtain hooks or rings, providing versatility in how curtains are hung and adjusted.

3. Load-Bearing Capacity

The load-bearing capacity of a curtain rail is a critical performance aspect. It determines the weight of the curtains that can be supported without compromising the rail’s functionality or stability.

– Heavy-Duty Rails: For large or heavy curtains, heavy-duty rails are essential. These rails are built to handle substantial weights and are often reinforced to ensure stability and longevity.

– Standard Rails: Standard curtain rails are suitable for lightweight to medium-weight curtains. It is important to select a rail that matches the weight of the curtains to avoid issues such as bending or sagging.

4. Installation Considerations

Proper installation is key to maximizing the performance of curtain rails. Factors to consider include:

– Mounting Hardware: High-quality mounting brackets and hardware are essential for securing the curtain rail to the wall or ceiling. They should be compatible with the rail and capable of supporting its load.

– Alignment: Accurate alignment of the curtain rail ensures smooth operation and prevents uneven wear on the rail and curtains. It is crucial to level the rail properly during installation.

– Maintenance: Regular maintenance, including cleaning and checking for any wear or damage, helps maintain the performance and longevity of the curtain rail.

In summary, the performance of curtain rails is influenced by the material quality, design features, load-bearing capacity, and installation practices. Selecting the right curtain rail involves considering these factors to ensure functionality, durability, and aesthetic appeal. Whether for residential or commercial applications, understanding these aspects will help in choosing a curtain rail that meets your needs and enhances the overall window treatment experience.